Share:

OVERVIEW

The federal regulations for the Underground Injection Control (UIC) program are found in Title 40 of the Code of Federal Regulations under the regulation from the Environmental Protection Agency (EPA). The Safe Drinking Water Act (SDWA) establishes requirements and provisions for the UIC program. Congress passed the SDWA in 1974. In part, the SDWA requires EPA to develop minimum federal requirements for UIC programs and other safeguards to protect public health by preventing injection wells from contaminating underground source of drinking water (USDWs).

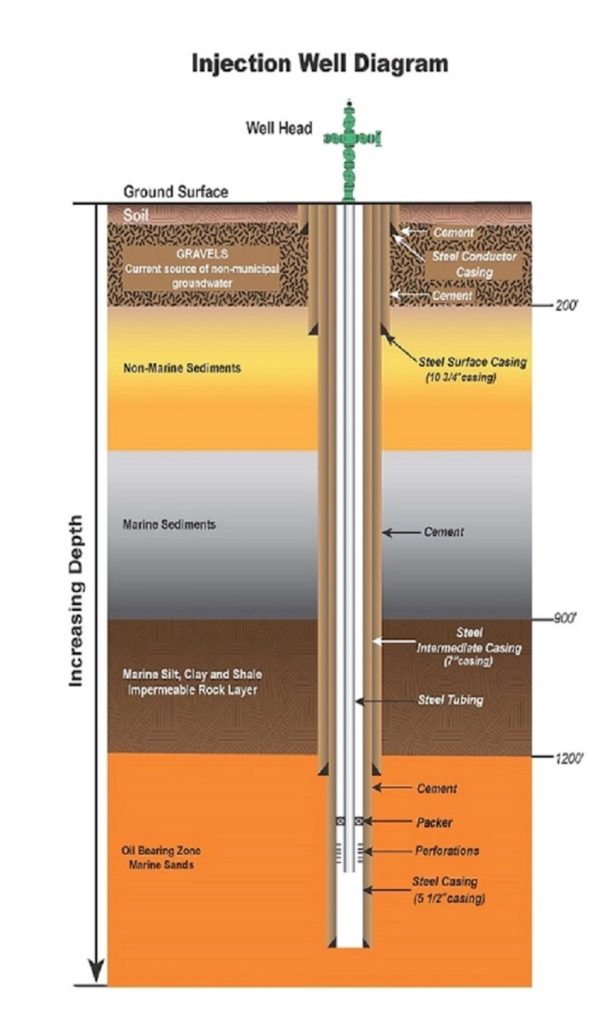

The UIC program consists of six classes of injection wells authorized under the SDWA. Each well class is based on the type and depth of the injection activity, and the potential for that injection activity to result in endangerment of an USDW.

- Class I wells are used to inject hazardous and non-hazardous wastes into deep, isolated rock formations.

- Class II wells are used exclusively to inject fluids associated with oil and natural gas production.

- Class III wells are used to inject fluids to dissolve and extract minerals.

- Class IV wells are shallow wells used to inject hazardous or radioactive wastes into or above a geologic formation that contains a USDW. This class of well is banned except when used as part of an environmental cleanup project

- Class V wells are used to inject non-hazardous fluids underground. Most Class V wells are used to dispose of wastes into or above underground sources of drinking water.

- Class VI wells are wells used for injection of carbon dioxide (CO2) into underground subsurface rock formations for long-term storage.

UIC regulations mandate the consideration of a variety of measures to assure that injection activities will not endanger USDWs. The concept of endangerment is defined in federal code of regulations (40 CFR 144.12).

Many UIC wells are regulated by states, tribes, and territories under delegation from the EPA. For example, the Class II program is delegated to 40 states, two tribes, and three territories under Sections 1422 or 1425 of the SDWA.[1]

SALTWATER DISPOSAL WELLS (CLASS IID)

As oil and natural gas are brought to the surface, they generally are mixed with salt water. On a national average, approximately 10 barrels of salt water are produced with every barrel of crude oil[2]. Geologic formations are selected to receive the produced waters, which, in some cases, are reinjected through disposal wells.

ENHANCED OIL RECOVERY WELLS (CLASS IIR)

Enhanced Oil Recovery (EOR) injection wells are used to increase production and prolong the life of oil-producing fields. Fluids consisting of brine, freshwater, steam, polymers, or carbon dioxide are injected into oil-bearing formations to recover residual oil and in limited applications, natural gas.

The injected fluids thin (decrease the viscosity) or displace small amounts of extractable oil and gas. Oil and gas is then available for recovery. In a typical configuration, a single injection well is surrounded by multiple production wells that bring oil and gas to the surface.

The UIC program does not regulate wells that are solely used for production. However, EPA does have authority to regulate hydraulic fracturing when diesel fuels are used in fluids or propping agents. During hydraulic fracturing, another enhanced recovery process, a viscous fluid is injected under high pressure until the desired fracturing is achieved, the fractures are then propped open using materials (proppants) such as sand or ceramic beads.

Enhanced recovery wells are the most numerous types of Class II wells. They represent as much as 80 percent of the total number of Class II wells. Under the UIC program, the EPA establishes minimum standards to prohibit underground injection that would endanger USDWs, and applicable UIC program regulations are established for each state to be administered either by EPA (direct implementation) or by the state which can apply for and obtain “primacy” to administer all or portions of the UIC program within the state.

Class II disposal fluids are primarily brines (salt water) that are brought to the surface while producing oil and gas (also known as produced water). Class II wells could also be used to inject fluids to enhance hydrocarbon production, such as CO2 in EOR projects. The number of active Class II wells varies from year to year based on fluctuations in oil and gas demand and production. There are approximately 180,000 Class II wells in the United States.

HYDROCARBON STORAGE WELLS

Hydrocarbon storage wells are generally used for the underground storage of crude oil and other hydrocarbons that are liquid at standard temperature. These hydrocarbons are typically stored in depleted oil and gas formations and naturally occurring or mined caverns.. The wells are designed for both injection and removal of the stored hydrocarbons. The hydrocarbons are injected for storage and later pumped back out for processing and use.

[1] USEPA, August 2020 https://www.epa.gov/uic/primary-enforcement-authority-underground-injection-control-program

[2] Veil, John, U.S. Produced Water Volumes and Management Practices in 2017, GWPC, February, 2020 https://www.gwpc.org/wp-content/uploads/2023/02/pw_report_2017___final.pdf

Additional Resources:

From The Groundwater Report to the Nation: Summary | Full Chapter

News

- GWPC Provides Comments to EPA on Louisiana Class VI UIC Program Revision Application

- GWPC Releases 2023 Produced Water Report

- US Produced Water Volumes & Management Practices in 2021

- RBDMS WellFinder Adds Kansas Data

- Updated State Guide Addresses Seismicity Induced by Fluid Injection

- FracFocus Launches New Public Website

- California’s RBDMS 3.0: WellSTAR Release 4 Goes Live

Publications

- Modern Oil & Gas Development: 2023 Update

- Produced Water Report: Regulations & Practices Updates (2023)

- Injection Wells: A Guide to Their Use, Operation, and Regulation (2021 Update)

- Potential Induced Seismicity Guide: A Resource of Technical and Regulatory Considerations Associated with Fluid Injection

- Well Integrity Regulatory Elements for Consideration: 2021 Edition

- State of Kansas Class II UIC Program Peer Review

- State of California Class II UIC Program Peer Review

- New Mexico Class II UIC Program Peer Review

- Produced Water Report: Regulations, Current Practices & Needs

- State Of West Virginia Class II UIC Peer Review

- State Oil And Natural Gas Regulations Designed To Protect Water Resources (3rd Edition)

- Underground Gas Storage Regulatory Considerations

- Ground Water Report to the Nation

- Ohio Class II Peer Review

- State Of Nebraska Class II UIC Program Peer Review

- State Of Utah Class II UIC Program Peer Review

- Potential Injection-Induced Seismicity Associated with Oil & Gas Development: A Primer on Technical and Regulatory Considerations Informing Risk Management and Mitigation

- State Oil And Gas Regulations Designed To Protect Water Resources

- Overview Of Groundwater Protection Regulations In Oil And Gas States

- State Oil & Gas Regulations Designed To Protect Water Resources

Comments

- Comments on EPA Applying the Supreme Court’s County of Maui v. Hawaii Wildlife Fund Decision in the Clean Water Act Section 402 National Pollutant Discharge Elimination System Permit Program

- Comments on EPA’s Draft National Water Program Guidance 2018-2019, Publication Number 800D17001

- Comments on Proposed USDA Forest Service Directive on Groundwater Resource Management